ALL THE COLORS IN THE WORLD

We offer a wide range of processes to finish accessories for clothing, leather goods, footwear and not only: glossy, matt, metallic, pearl, micalized, ceramic, rubberized and many others; as well as metal coatings, thanks to PVD technology, with colors ranging from precious gold to iridescence; and custom prints, with all possible finishes.

Filter by technology

Matt 5

Matt 20

Semishiny 100/50

Semishiny 100/100

Shiny

Shiny rubber

Matt rubber

Matt demi-soft

Matt Ice

Matt teal blue

Matt asphalt

Shiny cappuccino

Shiny old rose

Shiny warm ivory

Shiny wine

Matt sand

Shiny wood

Matt cotton

Shiny black

Matt white

Shiny metal grana magnum

Matt metal grana extra fine

Shiny metal ink blue

Shiny hologram

Shiny blue purple

Shiny gold mica

Shiny blue mica

Shiny blue sunstone

Matt pearl lace

Silver glitter light

Fairy tale

Gold glitter dark

Shiny white pearl

Shiny white warm pearl

Shiny grey pearl

Shiny pink pearl

Shiny white iride

Shiny dark iride

Shiny metal iride

Matt texture grey

Shiny shade cloud

Matt black cloud

Shiny black drops

Shiny green drops

Shiny yellow fluo

Shiny green fluo

Matt orange fluo

Matt pink fluo

Shiny glow in the dark

Matt glow in the dark

Matt grey stone

Matt candy snow

Matt deep see

Matt sandstone

Shiny brush strokes

Shiny agate

Matt shadows

Matt pink marble

Shiny miriad pro

Matt book antiqua

Matt font space

Matt black & white

Matt logo

Matt texture

Shiny spider web

Shiny marble

Matt stripes

Matt leather effect

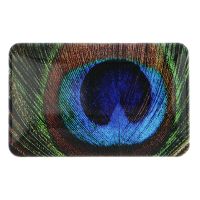

Shiny peacock

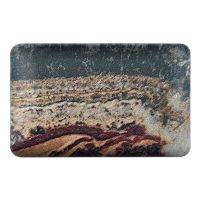

Matt rock mountain

Matt leaves

Shiny rose

Shiny handwrite

Matt volcano

Shiny silver

Shiny aluminum

Shiny chrome

Shiny dark chrome

Shiny warm chrome

Shiny copper

Shiny bronze

Shiny gold

Shiny dark copper

Shiny warm gold

Shiny gold1N

Shiny light gold

Shiny dark gold

Matt chrome

Matt dark chrome

Matt dark gold

Shiny rose gold

Sandblasted rose gold

Shiny gold14K

Sandblasted gold14K

Shiny black

Sandblasted black

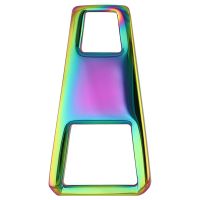

Shiny mix color

Sandblasted mix color

Shiny champagne gold

Sandblasted champagne gold

Shiny copper bronze

Sandblasted copper bronze

Shiny steel

Sandblasted steel

Shiny gun

Sandblasted gun

Shiny gold18K

Sandblasted gold18K

Shiny light gold

Sandblasted light gold

Shiny blue